How to choose geogrids for retaining walls construction?

When choosing the type of geogrid for the construction of retaining walls, three basic factors need to be considered: the design requirements, soil conditions, and anticipated loads.

Geogrids are commonly classified as biaxial or uniaxial according to different grid constructions. Also, geogrids are available in various materials such as plastic (PP and PE), fiberglass, polyester, and composite-geogrid. Each material possesses different properties that can influence their suitability for specific applications.

Selection of Biaxial or Uniaxial Geogrids for Retaining Wall:

Retaining walls experience both horizontal and vertical forces exerted by the soil.

Biaxial Geogrids: Biaxial geogrids have equal strength in both the longitudinal (machine) and transverse (cross-machine) directions. They provide effective reinforcement in two perpendicular directions, distributing the loads more evenly. Biaxial geogrids are commonly used in applications where the soil conditions are less predictable and require greater reinforcement.

Uniaxial Geogrids: Uniaxial geogrids are predominantly stronger in one direction (the longitudinal direction) and have less strength in the transverse direction. They are suitable for applications where the primary force acting on the retaining wall is in one direction, typically along the wall's height. Uniaxial geogrids are often used in scenarios where the wall height is substantial, and the forces applied are primarily vertical.

The selection between biaxial and uniaxial geogrids depends on the specific project requirements, soil characteristics, anticipated loads, and the design engineer's recommendations. Engineering analysis and calculations play a crucial role in determining the appropriate type of geogrid to ensure the stability and long-term performance of the retaining wall.

Geogrid Material Options:

Geogrids are available in various materials, and the choice of material depends on factors such as strength, durability, chemical resistance, and cost. Common geogrid materials:

Plastic (PP and PE): Geogrids made from polypropylene (PP) and polyethylene (PE) are lightweight, flexible, and have high tensile strength. They offer good resistance to chemicals and biological degradation. PP geogrids are commonly used in applications requiring moderate strength and stiffness, while PE geogrids are preferred when higher elongation and flexibility are required. These materials are cost-effective and easy to handle, making them popular choices for a wide range of retaining wall applications.

Fiberglass: Fiberglass geogrids are made from woven or stitched glass fibers coated with a polymer. They offer excellent tensile strength, high modulus, and resistance to creep and temperature variations. Fiberglass geogrids are chemically inert and highly durable, making them suitable for applications where long-term performance is crucial. However, they can be more expensive than plastic geogrids.

Polyester: Polyester geogrids are manufactured from high-strength polyester yarns coated with a protective polymer. They offer high tensile strength, low elongation, and good resistance to environmental factors such as UV radiation and chemical exposure. Polyester geogrids are commonly used in mechanically stabilized earth (MSE) walls, where soil reinforcement is required.

The selection of geogrid material for specific retaining wall project depends on factors such as project requirements, anticipated loads, soil conditions, and budget.

General specifications commonly considered when selecting geogrids for retaining walls:

Tensile Strength:

Geogrids should possess sufficient tensile strength to resist the applied forces and provide effective reinforcement. The tensile strength is typically specified as the ultimate tensile strength (UTS) and is measured in units of force per unit width (e.g., kN/m or lbs/ft). The UTS requirement depends on the anticipated loads, wall height, and soil conditions.

Aperture Size:

The aperture size refers to the opening size between the geogrid ribs or strands. It is essential to select a geogrid with an appropriate aperture size to allow for effective soil interlocking and prevent soil intrusion into the geogrid structure. The aperture size is typically specified as the maximum opening size or the nominal aperture size.

Junction Efficiency:

Junction efficiency is a measure of the geogrid's ability to transfer tensile forces from one rib or strand to another. It is expressed as a percentage and represents the strength of the connection between intersecting strands. Higher junction efficiency indicates better load transfer capability. Typically, a minimum junction efficiency requirement is specified in project specifications.

Strain Compatibility:

Geogrids should exhibit strain compatibility with the surrounding soil to prevent excessive deformation and maintain stability. Strain compatibility refers to the ability of the geogrid to deform and elongate along with the soil without experiencing significant strain differences. This property ensures that the geogrid and soil work together as a composite system.

Durability:

Geogrids used in retaining walls should be durable and resistant to degradation under environmental conditions. They should exhibit resistance to ultraviolet (UV) radiation, chemical exposure, and biological degradation. Specifications often include requirements for long-term durability and resistance to installation damage.

Roll Dimensions:

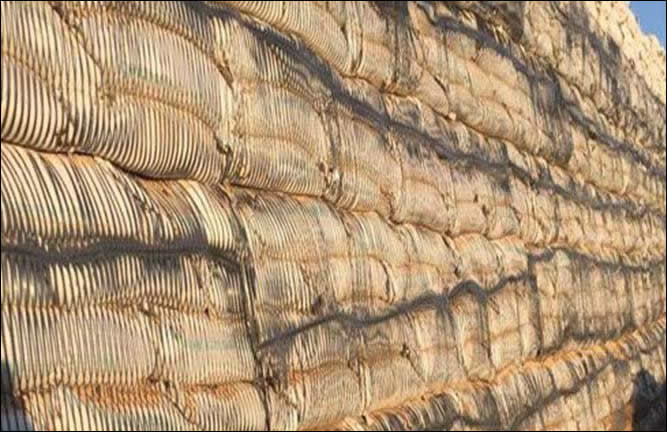

Geogrids are typically supplied in rolls, and their dimensions are specified in terms of roll width and length. The roll dimensions should be suitable for the specific project requirements, considering factors such as wall height, reinforcement layout, and ease of installation.

Selecting the appropriate type of geogrid and material for retaining wall construction is essential for ensuring the wall's stability, long-term performance, and cost-effectiveness. Biaxial and uniaxial geogrids offer different reinforcement characteristics and should be chosen based on the specific forces acting on the retaining wall. Geogrids made from plastic (PP and PE), fiberglass, polyester, and composite materials each possess unique properties that make them suitable for different applications. It is crucial to consult with geotechnical engineers, review project specifications, and consider soil conditions and anticipated loads to make an informed decision regarding the type and material of geogrid to be used.